Molding Capabilities

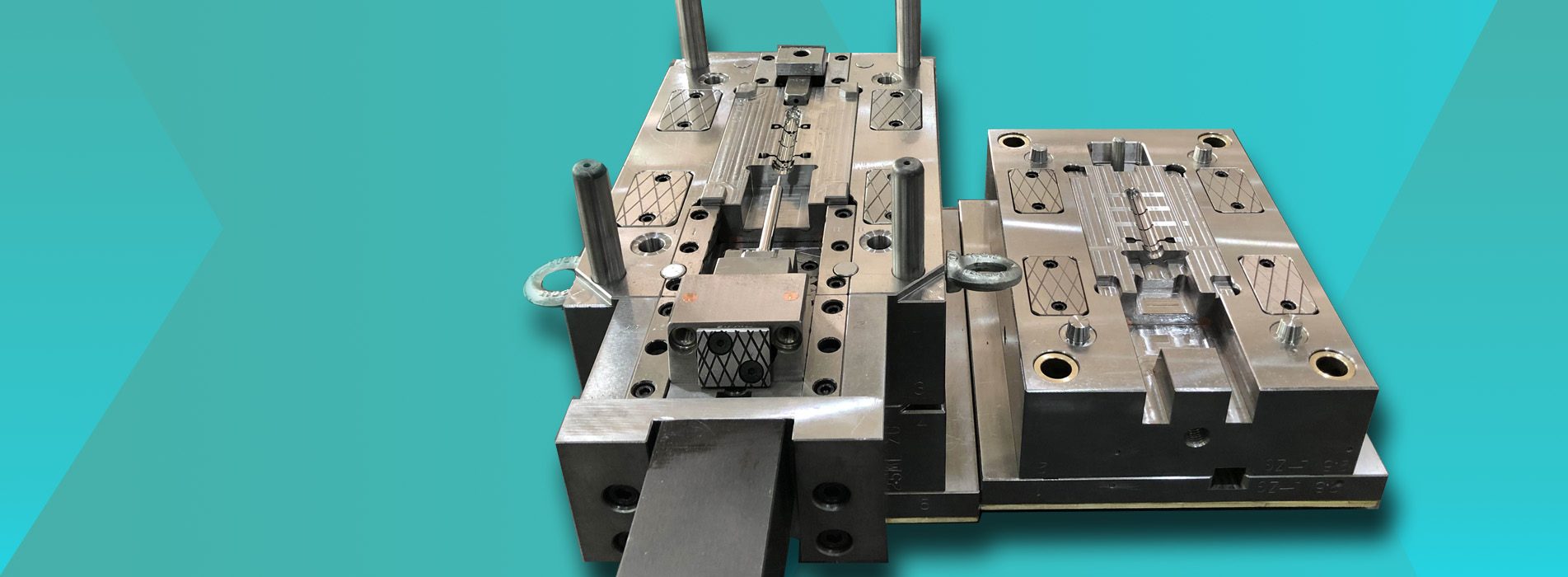

Tooling and Production:

IMo Plastic Mold manufactures custom plastic injection molds, plastic parts and CNC machined plastic prototypes. Our capabilities include overmolding, insert molding and family molds. We offer a variety of plastic materials, colors and surface finishes. Our proprietary mold frame exchange technology is one of the key factors why we can produce your injection molds and parts at such high speed and at such a low cost.

Overmolding:

IMO Plastic Mold has overmolding processes where one thermoplastic material is molded over another material to form one part. Our overmolding capabilities typically involve soft thermoplastic materials such as urethanes and thermoplastic elastomers (TPE) being overmolded onto hard plastic such as ABS or PC, for example.

Insert Molding:

This is an injection molding process by which metal inserts such brass nuts, screws, bushings or mesh filters are combined into one part by injecting thermoplastic around them. Our insert molding capabilities can include a variety of insert materials such as metal or ceramic.

Ultrasonic Welding:

IMO Plastic Mold ultrasonic welding process uses high frequency mechanical sound waves (ultrasonics) to crate molecular heat between thermoplastic materials so the plastic will melt and form a molecular bond between the parts to join two parts together.

Pad Printing:

A printing process that can transfer a 2D image onto a 3D object.

Silk Screening:

A printing technique that uses a woven mesh to support an ink-blocking stencil to receive a desired image.

Functional Testing by Customer Specification:

IMO Plastic Mold provides functional testing services required by customers. Typically testing includes leak testing, impact testing, and pressure testing.

Why IMO Plastic Mold?

Business and consumers alike have many options when it comes to buying goods and services. Injection mold companies are not all the same. What makes one product or service better than another can be determined by many factors, but ultimately, the answer comes down to: a quality product at a reasonably low cost, reliable customer service that cares about the customer’s needs, and speed by which the services are completed or the goods are delivered. So, Why IMO PlastiMold?

1.Low prices on plastic injection molds and plastic parts.

2.Fast and dependable service.

3.Trouble-free injection mold modifications.

4.Low and high volume production molds and parts— rapid prototype injection molds, production molds, and exportation molds.

5.The customer owns the injection mold.

6.No limitations on injection molding side actions.

7.Plastic parts sizes up to 48 inches long.

8.Value-added services include assembling, silk screening, pad printing, ultrasonic welding, and packaging.

9.ISO 9001 Certified Manufacturing Facilities.